Still Hardwiring? Connect it and Move On

Connectors outperform hardwiring at every stage of the product life

Get Connected

Connections are essential in your equipment. When you need an efficient solution that saves time, cost, and increases maintenance safety, choose industrial plug-and-play connectors from HARTING.

Connectorization vs. Hardwiring

Choosing connector-based wiring instead of hardwiring has its benefits at every stage of product life.

Installation Time

When hardwired control cabinets need to be disassembled, shipped, and reassembled, specialist contractors need to be hired. Lengthy testing to ensure the wiring has been connected correctly costs time. Plug & play connectors can be easily linked to each other and machinery, resulting in a simple, flexible, and versatile installation experiences.

When hardwired control cabinets need to be disassembled, shipped, and reassembled, specialist contractors need to be hired. Lengthy testing to ensure the wiring has been connected correctly costs time. Plug & play connectors can be easily linked to each other and machinery, resulting in a simple, flexible, and versatile installation experiences.

Labor Costs

Hardwiring often leads to extra labor costs. The assembling, testing, and repair of components takes a lot of time and efforts, requiring staff with special skills. The use of connectors dramatically reduces costs, since it increases efficiency and allows for savings of time and labor.

Hardwiring often leads to extra labor costs. The assembling, testing, and repair of components takes a lot of time and efforts, requiring staff with special skills. The use of connectors dramatically reduces costs, since it increases efficiency and allows for savings of time and labor.

Maintenance

Machine downtime is extremely costly for manufacturers. Fixing a hardwired machine requires a specialist maintenance engineer or contractor to attend, which is expensive from both a financial and time perspective. Using a Plug & Play set up, it is relatively easy and inexpensive to disconnect the unit and replace it.

Machine downtime is extremely costly for manufacturers. Fixing a hardwired machine requires a specialist maintenance engineer or contractor to attend, which is expensive from both a financial and time perspective. Using a Plug & Play set up, it is relatively easy and inexpensive to disconnect the unit and replace it.

Design and Lead Time

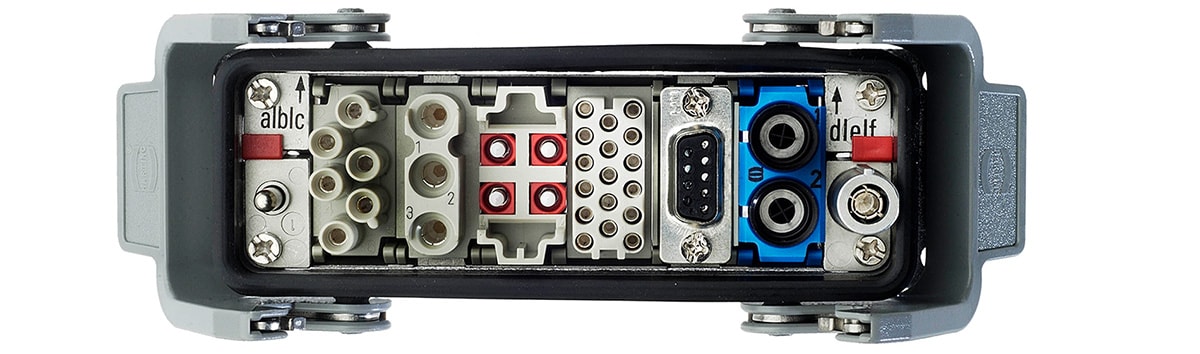

Using modules, power, control, and data transmission can take place side-by-side in one connector. The related contacts and inserts are designed for high-voltage/current, thermocouple, Profibus or Ethernet transmission. The modular principle increases the flexibility and saves space on the equipment, making it much easier for specialists to design the applications in the grid according to the latest technologies and trends, such as digitalization, modularization, or miniaturization.

Using modules, power, control, and data transmission can take place side-by-side in one connector. The related contacts and inserts are designed for high-voltage/current, thermocouple, Profibus or Ethernet transmission. The modular principle increases the flexibility and saves space on the equipment, making it much easier for specialists to design the applications in the grid according to the latest technologies and trends, such as digitalization, modularization, or miniaturization.

Flexibility

Whether you're looking to make a one-off item or relocate production to another part of the factory, manufacturing flexibility is key. Plug & play connectors allow production processes to be adapted quickly and simply, and can often be performed by machine operators themselves. Modular connectors from HARTING can combine power, signal and data into one connector, meaning they can be produced to your specific requirements.

Whether you're looking to make a one-off item or relocate production to another part of the factory, manufacturing flexibility is key. Plug & play connectors allow production processes to be adapted quickly and simply, and can often be performed by machine operators themselves. Modular connectors from HARTING can combine power, signal and data into one connector, meaning they can be produced to your specific requirements.

Testimonials from OEMs Who Switched to Connectors

A manufacturer of paper conveyors for commercial printing presses had been hardwiring over 200 wires to a control box of each unit. This process could take up to four days per unit. A switch to modular connectors reduced this number to as much as 2.5 days.

The manufacturer of large, material handling cranes, takes each one apart for shipment to the customer where it is reassembled. By transitioning from hardwiring to hybrid connectors, they cut field installation time from weeks to a mere 3-4 hours. The transition also erased the possibility of hardwiring errors during installation.

A builder of large, automated, precision-welding machines was hardwiring 300 contacts per unit. This process took a considerable amount of time to build, test, dismantle, and then to reassemble at the customers location. By switching to pluggable connectors, it decreased labor time, and therefore costs.

The maker of acoustic microscopes for analyzing the integrity of semi-conductors was planning a new model requiring 120 leads of varying voltages. By switching to two heavy connectors with 60 pins each, they streamlined interior wiring to achieve a small footprint and capture cost savings. Internal wiring bundles were eliminated, and less metal paneling was required.

Videos

Connectors Outperform Hardwiring

Roeslein Uses HARTING Connectors to Reduce Downtime

"Industrial Transformation Begins Here..." - Han-Modular®